Zaɓi zuwa: Samfuran gearbox ɗin dual-clutch suna rigar akwati biyu-clutch, harsashi mai goyan baya ya ƙunshi clutch da gearbox harsashi, bawo biyu da aka samar ta hanyar simintin matsi mai ƙarfi, a cikin aiwatar da haɓaka samfura da samarwa sun sami matsala mai wahala aiwatar da haɓaka ingancin inganci. , Cikakken cikakken ƙimar cancanta da kusan 60% 95% a ƙarshen hawan zuwa matakan 2020, Wannan labarin yana taƙaita hanyoyin magance matsalolin inganci na yau da kullun.

Wet dual-clutch watsa, wanda ke amfani da sabbin kayan aikin kascade, tsarin motsi na injin lantarki da sabon mai kunna wutan lantarki-hydraulic. Bakin harsashi an yi shi da babban simintin simintin ƙarfe na aluminum, wanda ke da halaye na nauyi mai nauyi da ƙarfin ƙarfi. Akwai famfo na hydraulic, ruwan mai mai mai, bututu mai sanyaya da tsarin sanyaya waje a cikin akwatin gear, wanda ya gabatar da buƙatu mafi girma akan ingantaccen aikin injina da aikin rufewar harsashi. Wannan takarda ta yi bayanin yadda ake magance matsalolin inganci kamar nakasar harsashi, ramin raguwar iska da ƙimar wucewar ɗigo wanda ke shafar ƙimar wucewa sosai.

1,Maganin matsalar nakasa

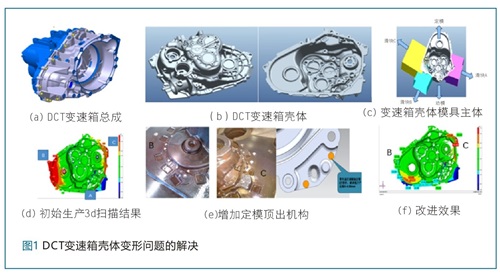

Hoto 1 (a) da ke ƙasa, Akwatin gear ya ƙunshi babban matsi na simintin simintin gyaran gyare-gyare na aluminum gami da mahalli mai kama. Kayan da aka yi amfani da shi shine ADC12, kuma kaurin bangon sa na asali shine kusan 3.5mm. Ana nuna harsashin akwatin gear a hoto na 1 (b). Matsakaicin girman shine 485mm (tsawo) × 370mm (nisa) × 212mm (tsawo), ƙarar shine 2481.5mm3, yanki mai tsinkaya shine 134903mm2, kuma nauyin net yana kusan 6.7kg. Bangaren rami ne mai zurfi mai bakin ciki. Yin la'akari da masana'antu da fasaha na fasaha na ƙirar, amincin samfurin samfurin da tsarin samarwa, an shirya ƙirar kamar yadda aka nuna a cikin Hoto 1 (c), wanda ya ƙunshi ƙungiyoyi uku na sliders, motsi mai motsi (a cikin jagorancin waje). rami) da ƙayyadaddun mold (a cikin shugabanci na rami na ciki), kuma an tsara ƙimar haɓakar thermal na simintin gyare-gyare don zama 1.0055%.

A zahiri, a cikin aiwatar da gwajin simintin gyare-gyare na farko, an gano cewa girman matsayin samfurin da aka samar ta hanyar simintin mutuwa ya sha bamban da buƙatun ƙira (wasu matsayi sun haura 30% kashe), amma girman mold ɗin ya cancanta kuma Yawan raguwa idan aka kwatanta da ainihin girman ya kasance daidai da dokar raguwa. Domin gano musabbabin matsalar, an yi amfani da 3D scanning na harsashi na zahiri da kuma ka'idar 3D don kwatantawa da bincike, kamar yadda aka nuna a hoto na 1 (d). An gano cewa yanki mai tushe na blank ya lalace, kuma adadin nakasar ya kasance 2.39mm a cikin yanki B da 0.74mm a yankin C. Domin samfurin ya dogara ne akan madaidaicin madaidaicin blank A, B, C na gaba. sarrafa ma'auni na ma'auni da ma'aunin ma'auni, wannan nakasar yana haifar da a cikin ma'auni, sauran girman tsinkaya zuwa A, B, C a matsayin tushen jirgin sama, matsayi na ramin ba shi da tsari.

Binciken musabbabin wannan matsala:

① Babban matsa lamba simintin mutu zane ka'idar ne daya daga cikin kayayyakin bayan demoulding, bada siffar da samfurin a kan tsauri model, wanda na bukatar sakamako a kan tsauri model na kunshin karfi ne mafi girma fiye da sojojin aiki a kan kafaffen mold jakar m, saboda da zurfin rami na musamman kayayyakin a lokaci guda, zurfin rami a cikin cores a kan tsayayyen mold da waje rami kafa surface a kan motsi mold kayayyakin yanke shawarar da shugabanci na mold rabuwa a lokacin da babu makawa sha wahala da gogayya;

②Akwai silidu a gefen hagu, ƙananan da dama na mold, waɗanda ke taka rawa wajen matsewa kafin rushewa. Ƙarfin tallafi mafi ƙanƙanta yana a saman B, kuma gabaɗayan hali shine ya ɓoye cikin rami yayin raguwar thermal. Babban dalilai guda biyu na sama suna haifar da nakasa mafi girma a B, sannan C.

Tsarin haɓakawa don magance wannan matsalar shine ƙara ƙayyadadden tsarin fitar da mutuwa Hoto na 1 (e) akan kafaffen shimfidar mutuwar. A B ya ƙãra 6 kafa mold plunger, ƙara biyu kafaffen mold plunger a cikin C, kafaffen fil sanda shi ne dogara ga sake saiti ganiya, lokacin da motsi mold clamping jirgin sama saita sake saiti lever danna shi a cikin wani mold, mold atomatik mutu matsa lamba bace, da baya. na farantin spring sa'an nan kuma tura saman kololuwa, yunƙurin inganta kayayyakin fito daga kafaffen mold, sabõda haka, don gane diyya demoulding nakasawa.

Bayan gyaran gyare-gyare, an rage nakasar lalacewa cikin nasara. Kamar yadda aka nuna a FIG.1 (f), nakasassu a B da C ana sarrafa su yadda ya kamata. Point B shine + 0.22mm kuma maki C shine + 0.12, wanda ya dace da buƙatun kwane-kwane na 0.7mm kuma ya sami samar da taro.

2. Maganin shrinkage rami da zubewar harsashi

Kamar yadda kowa ya sani, babban simintin simintin gyare-gyare wata hanya ce ta kafa wanda ake cika ƙarfen ruwa da sauri a cikin rami na ƙera ƙarfe ta hanyar amfani da wasu matsa lamba kuma yana ƙarfafawa cikin sauri a ƙarƙashin matsin lamba don samun simintin. Koyaya, dangane da halaye na ƙirar samfuri da aiwatar da simintin simintin gyare-gyare, har yanzu akwai wasu wuraren haɗin gwiwa masu zafi ko ramukan raguwar iska mai haɗari a cikin samfurin, wanda ya faru ne saboda:

(1) Yin simintin matsi yana amfani da babban matsa lamba don danna karfen ruwa a cikin rami mai saurin gaske. Ba za a iya fitar da iskar gas a cikin ɗakin matsa lamba ko kogon ƙura ba gaba ɗaya. Wadannan iskar gas suna shiga cikin ƙarfe na ruwa kuma a ƙarshe suna wanzuwa a cikin simintin gyare-gyare a cikin nau'i na pores.

(2) The solubility na gas a cikin ruwa aluminum da m aluminum gami ne daban-daban. A cikin tsarin ƙarfafawa, ba makawa gas yana haɗewa.

(3) Ƙarfe na ruwa yana ƙarfafawa da sauri a cikin rami, kuma idan babu ingantaccen ciyarwa, wasu sassan simintin za su haifar da raguwa ko raguwar porosity.

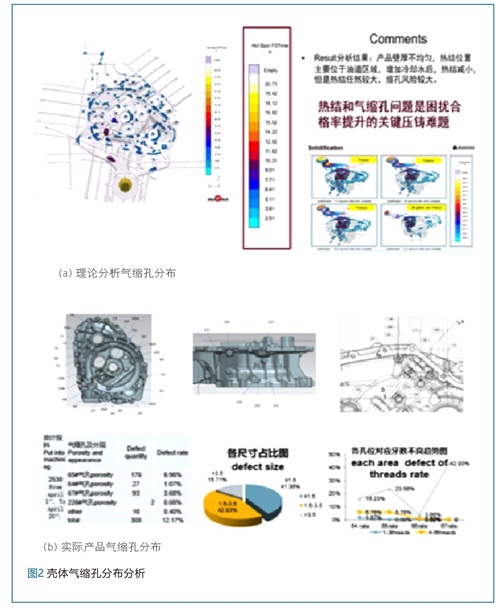

Ɗauki samfurori na DPT waɗanda suka shiga cikin samfurin kayan aiki da ƙananan matakan samar da kayan aiki a matsayin misali (duba Hoto 2): An ƙididdige yawan lahani na farkon ramin raguwar iska na samfurin, kuma mafi girma shine 12.17%, daga cikinsu akwai iska. shrinkage rami ya fi girma fiye da 3.5mm lissafin 15.71% na jimlar lahani, kuma iska shrinkage rami tsakanin 1.5-3.5mm lissafin 42.93%. Waɗannan ramukan ƙaƙƙarfan iska sun fi mayar da hankali ne a cikin wasu ramukan zaren zare da saman rufewa. Waɗannan lahani za su yi tasiri ga ƙarfin haɗin gwiwa, matsananciyar ƙasa da sauran buƙatun aikin tarkace.

Don magance waɗannan matsalolin, manyan hanyoyin sune kamar haka:

2.1TSARIN SANYA KWALLIYA

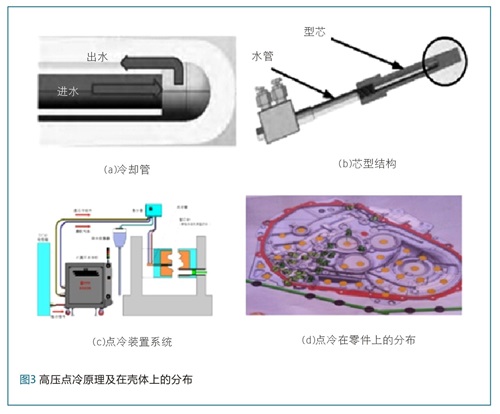

Ya dace da sassan rami mai zurfi guda ɗaya da manyan sassa masu mahimmanci. Sashin kafa na waɗannan sifofi yana da ƴan kogo masu zurfi kawai ko ɓangaren rami mai zurfi na ɗigon ja, da dai sauransu, kuma ƴan ƙirƙira an naɗe su da babban adadin ruwa na aluminum, wanda ke da sauƙin haifar da zafi mai zafi na mold, yana haifar da m. mold iri, zafi tsage da sauran lahani. Sabili da haka, wajibi ne a tilasta sanyaya ruwan sanyi a wurin wucewa na ƙirar rami mai zurfi. Sashin ciki na tsakiya tare da diamita fiye da 4mm ana sanyaya shi da 1.0-1.5mpa high-matsi ruwa, don tabbatar da cewa sanyaya ruwan sanyi da zafi, da kuma kewaye kyallen takarda na core iya fara da ƙarfi da kuma samar da wani. m Layer, don rage shrinkage da porosity hali.

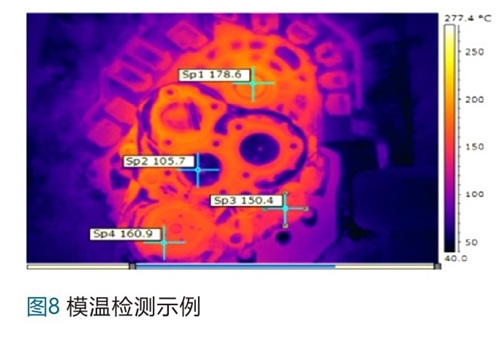

Kamar yadda aka nuna a cikin Hoto 3, haɗe tare da bayanan ƙididdigar ƙididdiga na simulation da samfurori na ainihi, an inganta shimfidar wuri mai sanyi na ƙarshe, kuma an saita babban matsi mai matsa lamba kamar yadda aka nuna a cikin Hoto 3 (d) a kan mold, wanda ya sarrafa yadda ya kamata. samfurin zafin jiki a cikin zafi hadin gwiwa yankin, gane da jeri solidification na kayayyakin, yadda ya kamata rage ƙarni na shrinkage ramukan, da kuma tabbatar da m kudi.

2.2Extrusion na gida

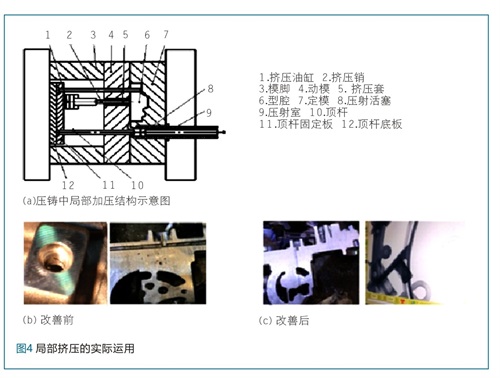

Idan kaurin bangon ƙirar ƙirar samfurin bai yi daidai ba ko kuma akwai manyan nodes masu zafi a wasu sassa, ramukan raguwa suna da yuwuwar bayyana a cikin ingantaccen ɓangaren ƙarshe, kamar yadda aka nuna a FIG. 4 (C) kasa. Ba za a iya hana ramukan raguwa a cikin waɗannan samfuran ta hanyar aiwatar da simintin mutuwa da haɓaka hanyar sanyaya ba. A wannan lokacin, ana iya amfani da extrusion na gida don magance matsalar. Jadawalin tsarin tsarin matsa lamba kamar yadda aka nuna a cikin adadi 4 (a), wato shigar da kai tsaye a cikin silinda, bayan narkakkar da aka cika a cikin mold kuma ya ƙarfafa kafin, ba gaba ɗaya ba a cikin ruwa mai ƙarfi na ƙarfe a cikin rami, na ƙarshe. solidification lokacin farin ciki bango ta extrusion sanda matsa lamba tilasta ciyar don rage ko kawar da shrinkage kogon lahani, domin samun high quality na mutu simintin gyaran kafa.

2.3Extrusion na sakandare

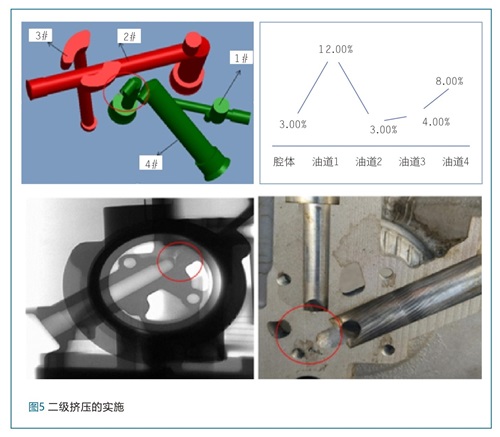

Mataki na biyu na extrusion shine saita silinda bugun jini sau biyu. Na farko bugun jini ya kammala wani bangare na gyare-gyaren rami na farko na farko, kuma lokacin da ruwa na aluminum da ke kewaye da shi ya karu a hankali, aikin extrusion na biyu ya fara, kuma an sami sakamako biyu na pre-simintin da extrusion a ƙarshe. Ɗauki gidan gearbox a matsayin misali, ƙimar da ta dace na gwajin gas na gidan gearbox a farkon matakin aikin bai wuce 70%. Rarraba sassan yoyon fitsari galibi shine mahadar hanyar mai 1# da kuma hanyar mai 4# (ja a hoto na 5) kamar yadda aka nuna a kasa.

2.4TSARIN CIN GUDU

Tsarin simintin gyare-gyaren simintin gyare-gyaren ƙarfe shine tashar da ke cika rami na ƙirar simintin gyare-gyare tare da narkakken ruwa na ƙarfe a cikin ɗakin latsawa na inji mai mutuƙar zafi a ƙarƙashin yanayin zafi mai zafi, matsa lamba da sauri. Ya haɗa da madaidaicin mai gudu, mai tseren giciye, mai gudu na ciki da tsarin shaye-shaye. An shiryar da su a cikin aiwatar da rami mai cike da ƙarfe mai cike da ruwa, yanayin kwararar ruwa, saurin gudu da matsa lamba na canja wurin ƙarfe na ruwa, tasirin shayewa da mutuƙar ƙima suna taka muhimmiyar rawa a cikin fannoni kamar yanayin ma'auni na thermal na sarrafawa da ƙa'ida, sabili da haka , Gating tsarin da aka yanke shawarar mutu simintin gyaran fuska ingancin da kuma muhimmanci factor na ciki microstructure jihar. Zane da kammala tsarin zubewa dole ne su dogara ne akan haɗin ka'idar da aiki.

2.5ProceOingantawa

Die simintin tsari tsari ne mai zafi wanda ke haɗawa da amfani da na'ura mai mutuƙar mutu, mutu simintin simintin da ƙarfe na ruwa bisa ga tsarin da aka riga aka zaɓa da sigogin tsari, kuma yana samun mutun simintin tare da taimakon wutar lantarki. Yana ɗaukar kowane nau'i na la'akari, Irin su matsa lamba (ciki har da ƙarfin allura, takamaiman matsa lamba, ƙarfin faɗaɗawa, ƙarfin kulle ƙira), saurin allura (ciki har da saurin naushi, saurin ƙofar ciki, da sauransu), saurin ciko, da sauransu.) daban-daban yanayin zafi (narkewar zafin jiki na ruwa karfe, mutu simintin zafin jiki, mold zafin jiki, da dai sauransu), lokuta daban-daban (cika lokaci, matsa lamba riƙe lokaci, mold riƙe lokaci, da dai sauransu), thermal Properties na mold (zafi canja wurin kudi, zafi). Yawan iya aiki, yanayin zafin jiki, da dai sauransu), kaddarorin simintin gyare-gyare da kaddarorin thermal na ƙarfe na ruwa, da sauransu.

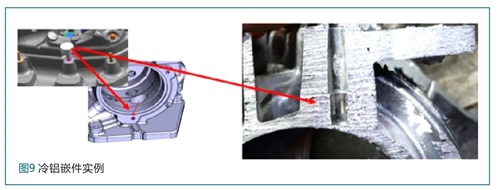

2.6Amfani da sababbin hanyoyin

Don magance matsalar yoyon sassa na sassan da ke cikin takamaiman sassan harsashi na gearbox, an yi amfani da maganin katangar aluminium mai sanyi a matsayin majagaba bayan tabbatar da bangarorin samarwa da buƙatu. Wato, ana ɗora shingen aluminium a cikin samfurin kafin cikawa, kamar yadda aka nuna a hoto na 9. Bayan cikawa da ƙarfafawa, wannan abin sakawa ya kasance a cikin ɓangaren ɓangaren don magance matsalar raguwar gida da porosity.

Lokacin aikawa: Satumba-08-2022